The Impact of Polymer Molecular Weight Distribution on Processing

페이지 정보

작성자 Jacinto Gowllan… 작성일25-12-22 10:21 조회2회 댓글0건관련링크

본문

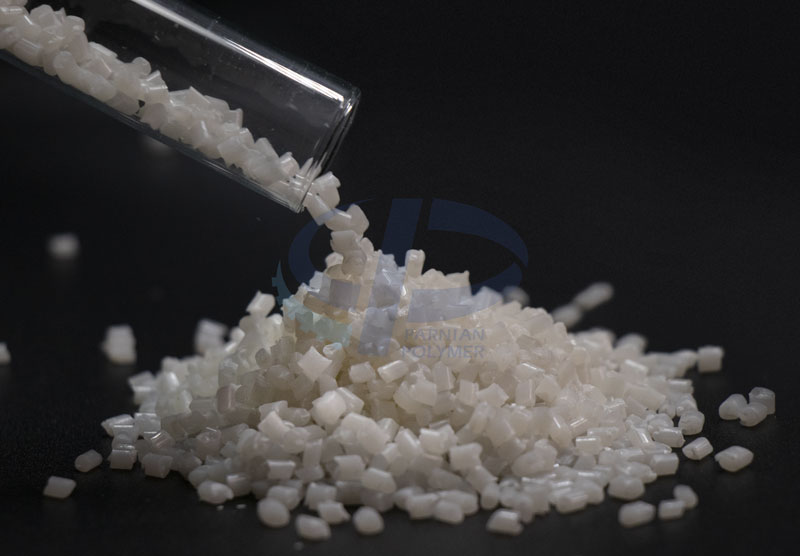

The range of chain lengths within a polymer sample plays a fundamental role in its processing characteristics. Polymer chains vary significantly in length; instead, they consist of a broad spectrum of molecular sizes, which together form its molecular weight heterogeneity. This heterogeneity affects core characteristics including melt flow, shear response, and heat resistance, all of which directly impact processing methods like plastic shaping processes including calendering and thermoforming.

Polymers with a narrow molecular weight distribution tend to have predictable melt flow profiles. This makes them easier to control during processing because they melt and flow at a more predictable rate. However, they can be less suitable for high-speed operations because their viscosity remains elevated under shear. This means that increased power consumption is necessary, and there is a increased likelihood of surface irregularities.

In contrast, materials with wide MWD contain a mix of short and long chains. Shorter chains serve as internal plasticizers, reducing overall viscosity and improving flow. The long chains provide strength and elasticity, helping the material to resist deformation during cooling. This combination allows for efficient operation under milder thermal conditions and faster cycle times, which is why most manufacturing sectors prefer wide-MWD grades.

The ratio of short to long polymer chains also affects the integrity and consistency of the molded component. Wide MWD enhances shape retention and minimizes distortion because the material undergoes uniform phase transition. However, too broad a distribution may lead to inconsistencies in key performance metrics like elongation and fracture toughness, especially if the oligomer content exceeds optimal levels.

Processing conditions must be adjusted based on the molecular weight distribution. For example, a resin rich in high-MW components may require increased thermal input and slower throughput to completely plasticize. Conversely, a polymer with many short chains may degrade if exposed to excessive heat or shear. Assessing chain length heterogeneity allows processors to optimize parameters like screw speed, pressure, and cooling rates to achieve the optimal trade-off between output rate and part integrity.

Ultimately, MWD is far more than a structural metric—it is a practical tool for designing efficient processing strategies. By engineering molecular profiles for specific applications, operators can streamline operations, lower emissions, and تولید کننده گرانول بازیافتی deliver superior components. Mastering MWD is crucial for all stakeholders in plastics manufacturing from technicians and R&D teams.

댓글목록

등록된 댓글이 없습니다.