Sustainable Plastic Extrusion Methods

페이지 정보

작성자 Nickolas Cowart 작성일25-12-22 07:14 조회2회 댓글0건관련링크

본문

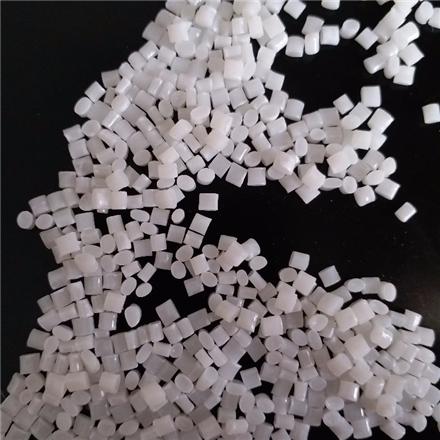

Sustainable practices in plastic extrusion processes are becoming increasingly important as industries strive to reduce environmental impact and meet regulatory demands. A foundational approach to greener operations is selecting the right raw materials. Choosing post-consumer or post-industrial recycled feedstocks reduces the demand for new petroleum based products and helps divert plastic waste from landfills. Leading manufacturers now embed post consumer and post industrial recycled content without compromising product quality.

Minimizing energy use remains a top priority. Modern extrusion machines are designed with energy recovery systems and variable frequency drives that adjust motor speed based on demand. This reduces unnecessary power consumption during non-peak operating hours. Routine servicing of thermal components and insulation layers also ensures that heat is retained efficiently, minimizing energy waste.

Waste reduction at the source is essential. Scrap material generated during start up, shutdown, or quality control can be collected, ground, and reintroduced into the extrusion process. Internal material recovery circuits allow for تولید کننده گرانول بازیافتی nearly zero waste in many cases. Staff must be educated to reduce excess usage and avoid over extrusion which leads to excess scrap.

Thermal regulation systems in production lines can be optimized by capturing and recirculating chilled fluid. Closed loop chillers with filtration and temperature control reduce freshwater consumption and prevent thermal pollution. Additionally, using biodegradable or compostable additives in certain applications can make the final product more environmentally friendly without affecting performance.

Supply chain transparency plays a role too. Partnering with suppliers who prioritize sustainable sourcing and ethical manufacturing ensures that sustainability extends beyond the factory floor. Certifications such as ISO 14001 or Cradle to Cradle can guide companies in adopting best practices.

Sustained enhancement using digital tracking helps identify inefficiencies. IoT devices and analytics platforms monitor energy use, material throughput, and emissions in real time, allowing for quick adjustments. Empowering workers with green performance metrics and encouraging innovation from the shop floor can lead to unexpected but effective solutions.

Through holistic adoption of these strategies, plastic extrusion operations can significantly reduce their environmental footprint while maintaining productivity and quality. Sustainability is not a one time initiative but an ongoing commitment that benefits both the planet and the business in the long term.

댓글목록

등록된 댓글이 없습니다.